Forge Furnace Modernizations

Forge furnace upgrades on seven industrial furnaces to modernize and reduce downtime.

Services

Combustion Controls Upgrade | Combustion Upgrade

Industry

Metals

Challenge

Solution

We delivered forge furnace upgrades that were installed on time, within budget, and our resources allowed their personnel to remain focused on their daily jobs.

Details

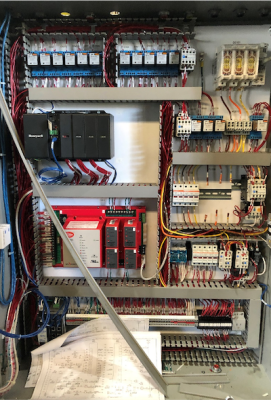

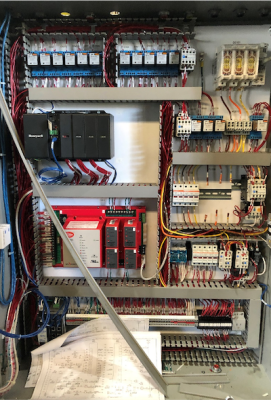

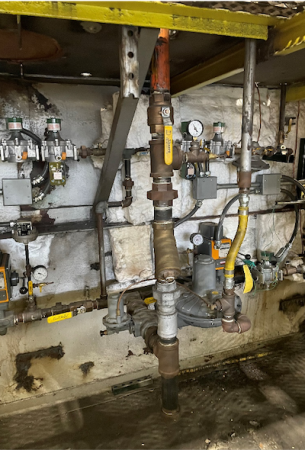

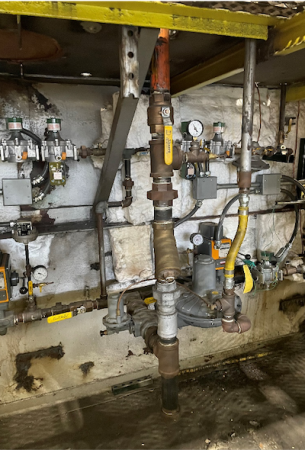

A client in the forging industry requested that our team design modernizations to seven of their forge furnaces. They had been experiencing frequent downtime for maintenance. As such, the forge furnace upgrades included replacing entire control enclosures with modern equivalents and upgrading the combustion piping. By doing so, the furnaces were to meet modern standards.

We have a thorough understanding of modern furnace safety codes, such as NFPA 86, from numerous completed projects for customers in the forging industry. Therefore, our team of electrical/controls engineers were to design control enclosures that would meet the customer’s requirements and the code requirements. Our mechanical engineers designed the combustion upgrades to meet the code and added new devices to make maintenance and operations easier for the client.

In the end, we designed, procured materials, and assembled all seven control enclosures. Also, we procured all mechanical materials that would be needed for the upgrade. To start, we shipped everything to the client in conveniently packaged kits for each furnace. And once the client’s contractors completed installation, we returned on-site for startup of the new controls. In conclusion, the client received seven furnaces that were back up and running with all modern controls and upgraded piping systems. Additionally, we provided all engineering drawings so the client has accurate documentation for years to come.

Our team worked together with the client to understand their needs and complete the portions of the project that the client could not complete themselves. As a result, this teamwork delivered another successful project.