Snack Food Oven Upgrade

Manufacturing Food Oven Upgrade to increase reliability and production.

Service

Combustion Project Management | Combustion Design & Engineering

Industry

Food & Beverage

Challenge

Solution

Details

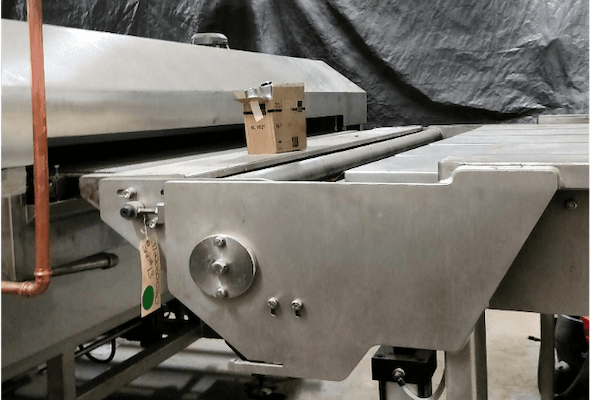

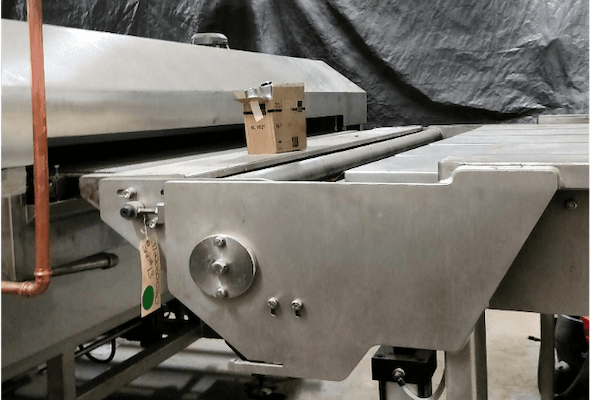

A client in the food and beverage industry had an unreliable snack food oven that was experiencing frequent downtime. As a result, they consulted with us for engineering and project management support to improve reliability.

As part of the project, the client desired to replace the combustion burner and switch from direct to indirect heating. This was to improve quality. Therefore, we began by surveying the oven for NFPA 86 compliance. Once completed, we provided our recommendations so they would be included in the scope of work and budgeted within the project.

Once the budget was approved, we provided project management and engineering support for the manufacturing food oven upgrade. As such, the client issued a contract to the oven manufacturer to perform the upgrade while we acted as a liaison between the vendor and client. Additionally, we provided engineering drawing reviews and ensured the vendor had all the information needed for project design and execution.

Then, we created a schedule for the project that met the client’s timing and production needs. During final design, we took on-site measurements verifying the vendor’s solution fit and maintaining room for normal forklift traffic. While coordinating shipment of new equipment, including some overseas, we took lead times into account to deliver on schedule. Additionally, one of the burner panels was found to be beyond repair, requiring reverse engineering and fabrication of a new panel. We accomplished that for the client.

Once all the equipment arrived, the oven was shutdown and we coordinated electrical and mechanical installation teams to perform the upgrade. As a result, the new oven burner and equipment, upstream material handling equipment, and electrical/controls system were installed. And we commissioned them to integrate the existing controls with the upgraded oven. During the project, we supervised all construction including installation of new burner exhaust vents to safely vent the combustion gas according to NFPA 86 requirements.

NFPA compliant rotary furnace upgrades for metals manufacturing company.